List of 10 milestone crashworthiness publications, which led to the development of macro element methodology

- Alexander, J. M. An approximate analysis of the collapse of thin cylindrical shells under axial loading, Q. J. Mech. Appl. Math., 13, 1, 10-15, 1960

- Johnson, W., Impact Strength of Materials, Edward Arnold (Publishers) Limited, 1972

- Johnson, W. and Mamalis, A. G., Crashworthiness of Vehicles, Mechanical Engineering Publications Ltd London, 1978.

- Kecman, D., Bending collapse of rectangular and square section tubes in relation to the bus roll over problem, PhD Thesis, Canfield Institute of Technology, UK, (1979).

- Structural Crashworthiness (Jones, N. & Wierzbicki, W. Editors) , Butterworth, 1983

- The Manual of Crashworthiness Engineering, (Wierzbicki & Abramowicz main contributors) Center of Transportation Studies, Massachusetts Institute of Technology, 1988-1991.

- Norman Jones, Structural Impact, Cambridge University Press, 1989.

- Abramowicz, W., Wierzbicki, T., Axial crushing of multicorner sheet metal columns., J. App. Mech., 56, 1, 113-120, (1989).

- Abramowicz, W., Macro element method in crashworthiness of Vehicles in Crashworthiness – energy management and occupant protection (Ambrosio J. Editor), SpringerWienNewYork, 2001.

- Abramowicz, W., An alternative formulation of the FE method for arbitrary discrete/continuous models, Int. J. Impact Engng., 30, 8-9, 1081-1098, (2004).

Pictures and movies on this page illustrate typical applications of Visual Crash Studio in synergetic design/calculation process.

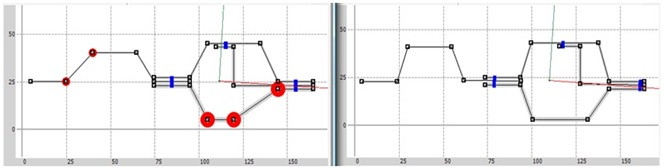

1) Design of a thin walled cross section for optimal crash performances (initial and final design). Red marks indicate flaws of initial design concept, (source VCS online help).

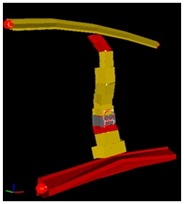

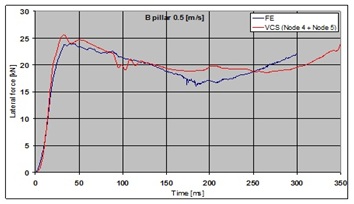

2) Quasi static crushing of B-pillar assembly – Chrysler Neon, VCS vs. LS DYNA (VCS: 13 macro elements CPU – 46 sec. on laptop).

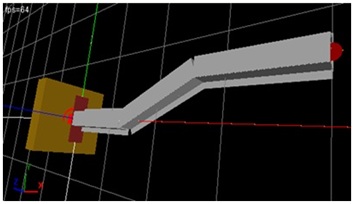

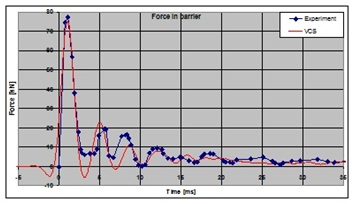

3) Dynamic crushing of S frames – experiments by JSAE, (VCS: 3 macro elements, CPU – 1 sec. on laptop)

4) Dynamic crushing of Toyota Yaris Frame Model (Courtesy of Helia Technology)

The VCS model consisted of 200 macro elements is calculated in 150 seconds on new generation laptop machine. Crash response time set to 160 milliseconds.

Detailed information about Macro Element Methodology is available in Crash Academy’s Publications section

5/5